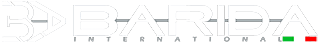

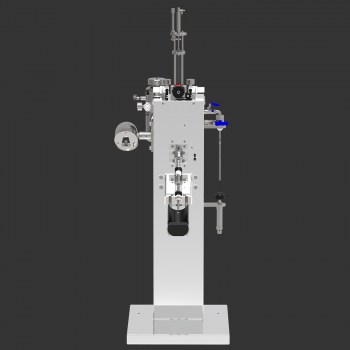

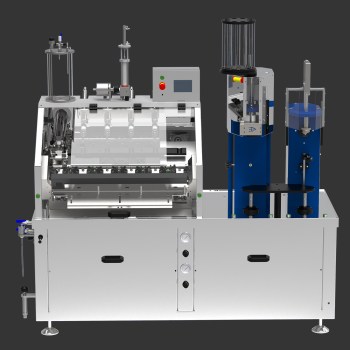

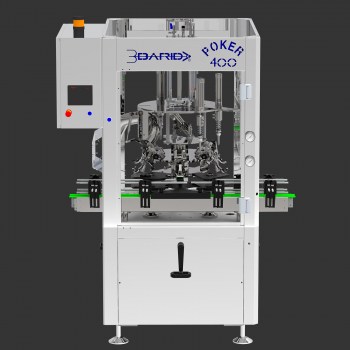

The monobloc semi-automatically performs the processing steps according to the traditional method.

Triblock filling machine suitable for working with glass bottles form 375 up to 1500 ml.

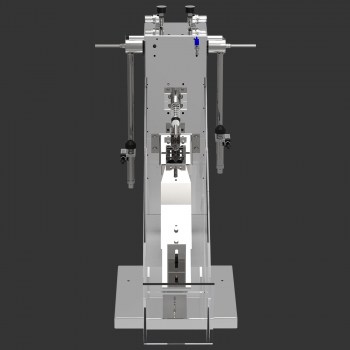

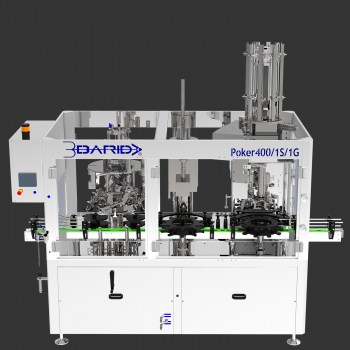

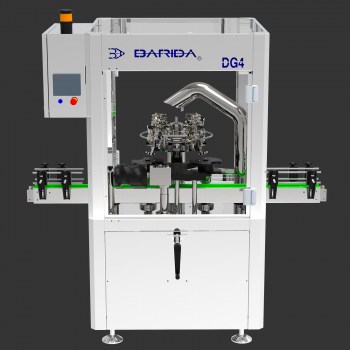

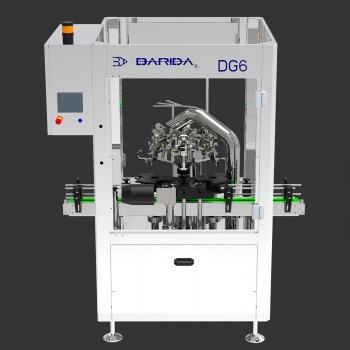

Innovative monoblock with two turrets that combines in one machine the pricipal operations of the classic method.

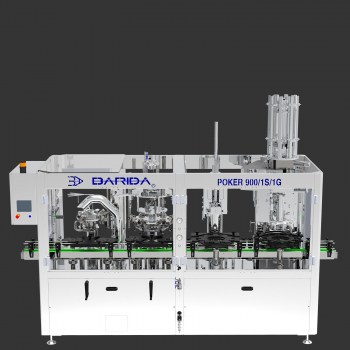

POKER 900/1S/1G is a compact and efficient monoblock; fully automatic, it allows the operator to devote himself solely to the logistics of loading and unloading the bottles.

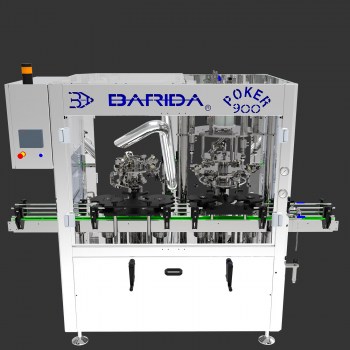

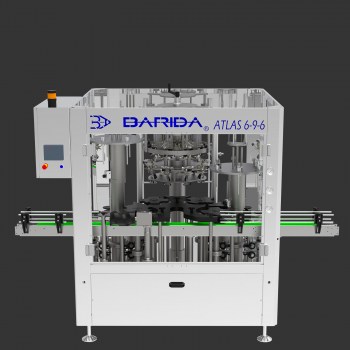

Monobloc consisting of three continuously rotating turrets, one for each processing stage.